About

Find Out More About Us

A GLOBAL PROVIDER OF NONDESTRUCTIVE TESTING SERVICES TO OFFSHORE & ONSHORE PIPELINES

Learn More

A GLOBAL PROVIDER OF NONDESTRUCTIVE TESTING SERVICES TO OFFSHORE & ONSHORE PIPELINES

We have successfully worked with industry-leading energy and industrial producers, contractors, and engineering firms on large-scale projects around the globe.

We offer complete project management on every aspect of the inspection process: from the inspection design and procedure qualification, to service personnel training and deployment, equipment logistics, through onsite supervision of project execution, and expert data analysis reports.

Our Activity

Check our Activity

CONVENTIONAL NDT

Conventional NDT techniques, such as radiography (RT), manual ultrasonic testing (UT), liquid penetrant testing (PT), magnetic particle testing (MPT) and more, are all standard services UT Quality provides

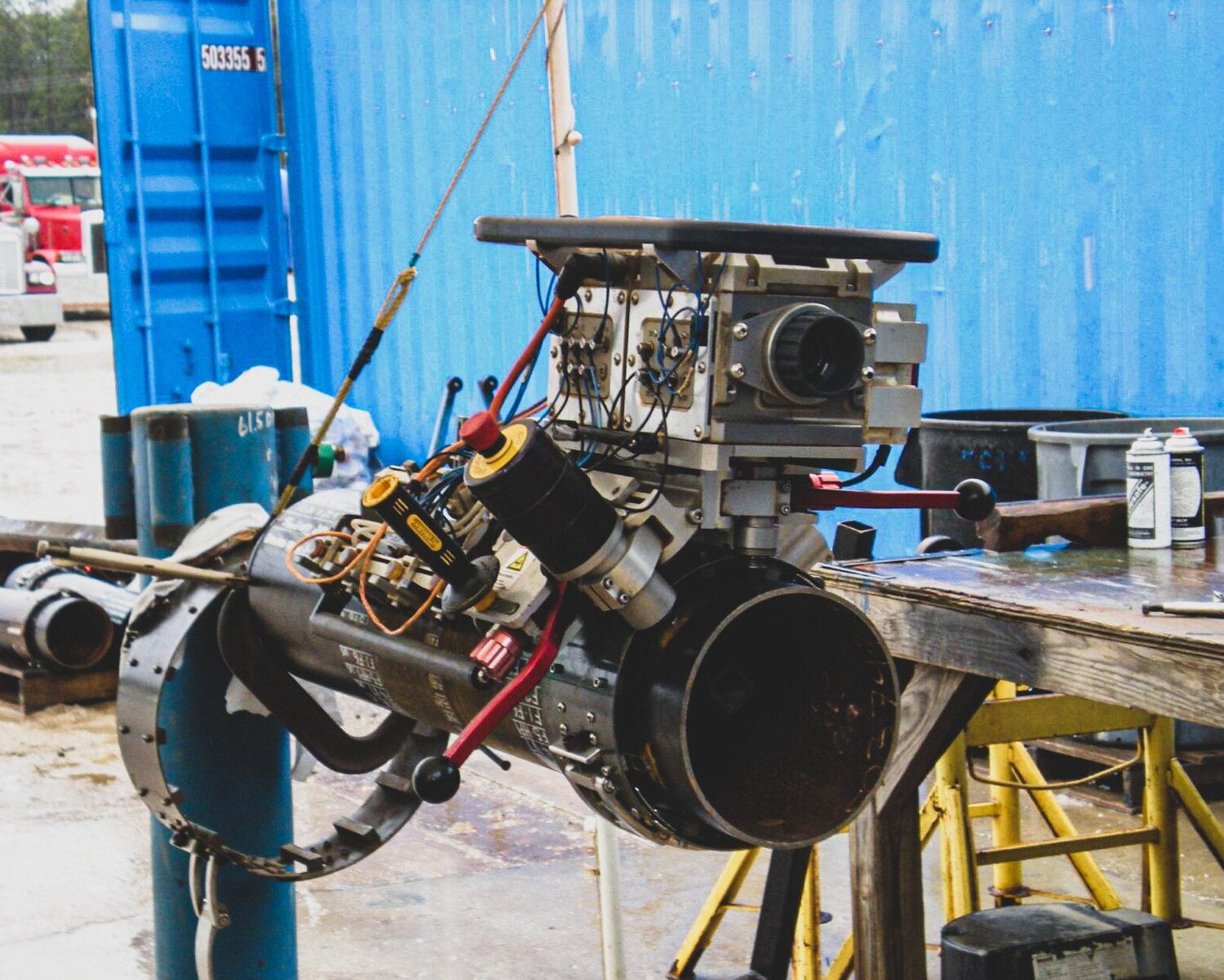

ADVANCED NDT

UT Quality specializes in advanced NDT techniques like its patented AUT system, UT Scan, which combines multiple NDT technologies in a single inspection.

Equipment

Learn More About Our Equipment

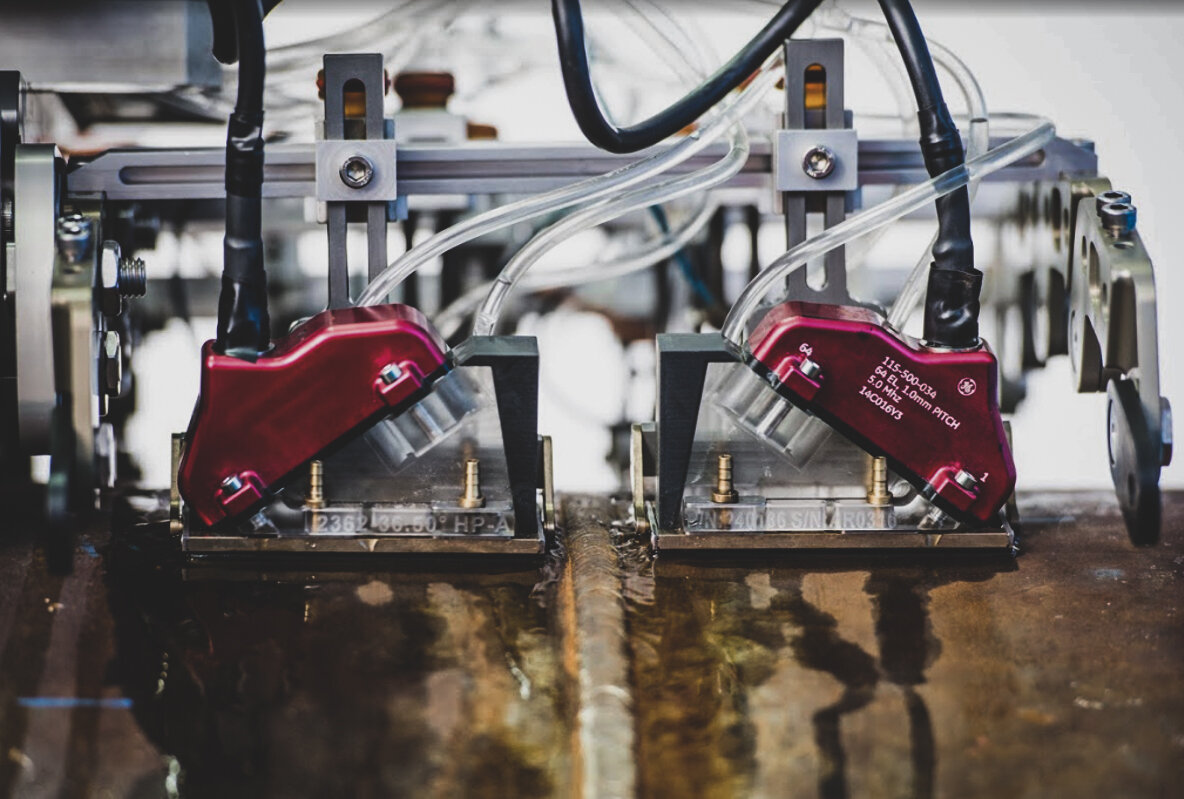

UT Scan

UT Scan is a hybrid unit that combines phased array with conventional time-of-flight diffraction (ToFD) and basic pulse-echo technologies in a single inspection, providing unparalleled detection accuracy.

Benefits:

- With a uniquely designed pulser/receiver, eliminate the effect of noise from the firing line

- Real-time results and feedback allow welders to repair on the spot

- Radiation free = no lost time or disruption to surrounding workers

- Detect critical defects that X-ray cannot (cracks, non-fusion), greatly reducing the risk of failure